Legato

Overview

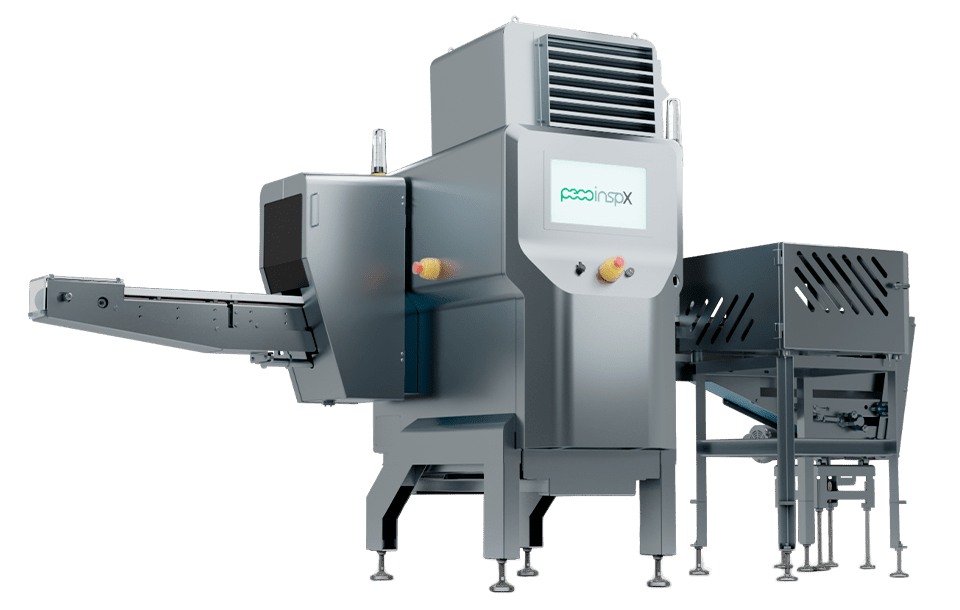

LEGATO X-RAY INSPECTION SYSTEM

Introducing SeamTrac Legato: The first inline, 360-degree, non-contact seam inspection system. SeamTrac Legato sets a new standard in canning quality control with real-time defect detection, advanced seamer monitoring, and precise headspace control.

Multiple X-ray inspection beams with overlapping coverage enables the Legato to inspect within multi-layered seams to identify a range of defects.

The SeamTrac Legato Inspection System delivers non-contact inspection at speeds up to 1200 CPM. System mounts on the existing single file seamer discharge conveyor and only requires 7.5’ of linear space. It provides early detection of seam defects, ejecting critical defective containers from the line, minimizing waste and further processing.

SeamTrac is designed to detect reliable deviations and defects in seam integrity. It monitors seamer performance in real-time, helping operators identify potential issues before they impact product quality.

Features

Inline Inspection of Every Can

Advanced Seamer Tracking

Headspace Monitoring

Return on Investment

Typical Applications

Droops

Cut/Cracked Seam

Knocked Down Flange

False Seam

Vee, U-shape, Spur, Lipper

Short Cover/Body Hook

Seam Wrinkle

Lap Defects

Insufficient Overlap

What Makes Peco Inspx X-ray Systems Different?

High Speed Operations

Service

Software

Made in America

Tech Specs

Technical Information

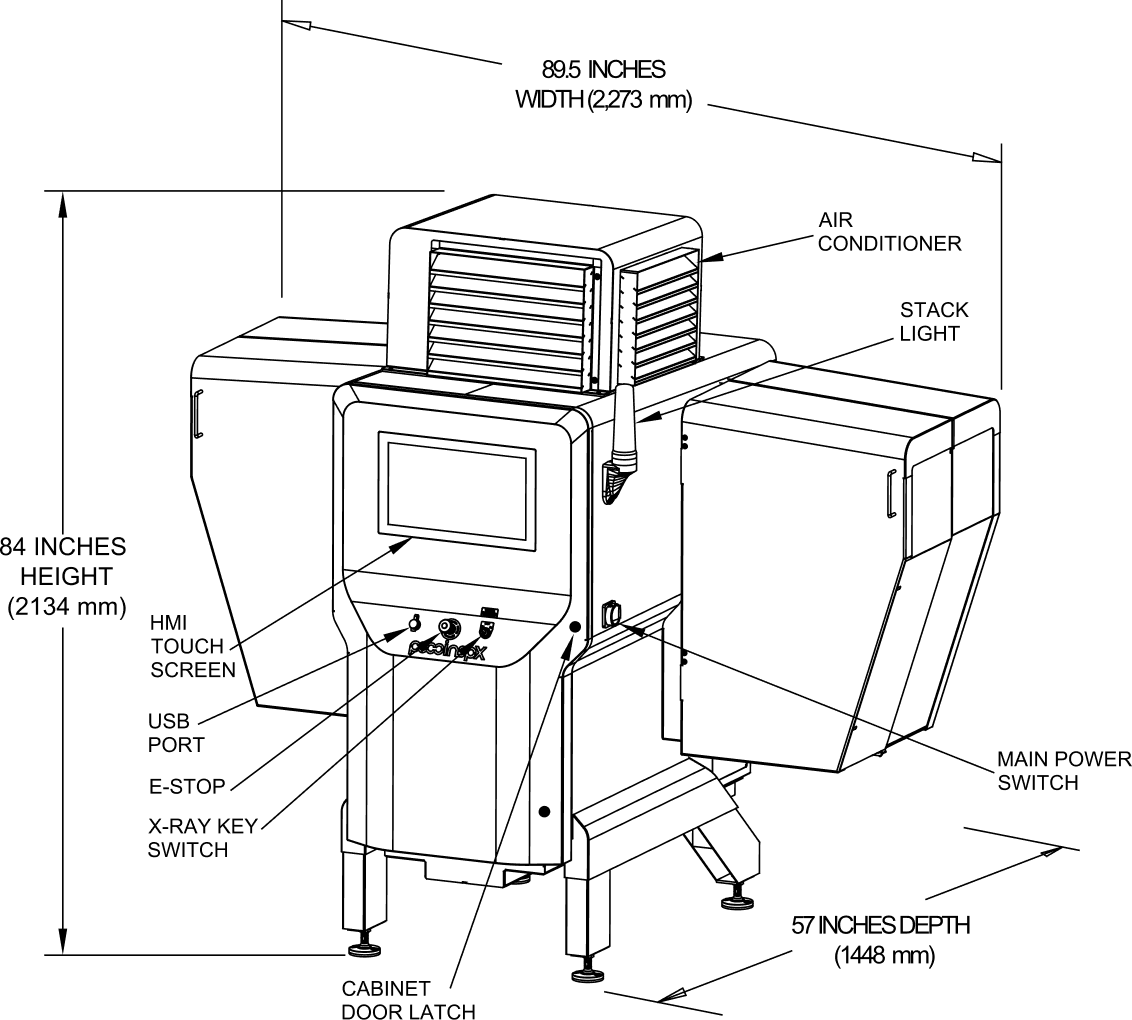

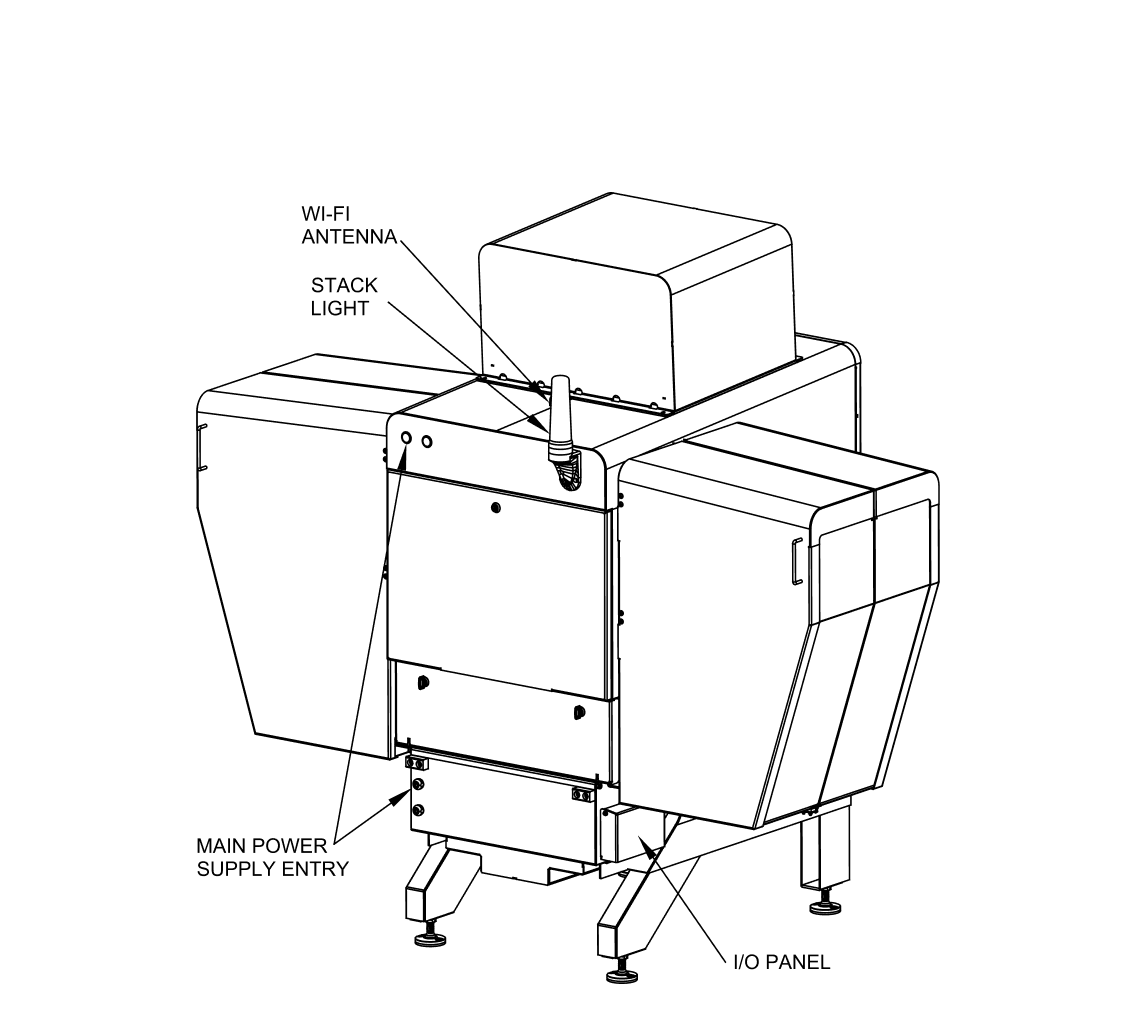

Machine Architecture

X-ray Tube Configuration

Conveyor

Aperture Size

Environment

Line Speed

Input Voltage

Air Supply

Ambient Temperature

Air Conditioning

Diode Size

Container Ejection

Dimensions (LxDxH)

Safety Rating

Computer

Connectivity (Optional)

Supported SCADA Systems

Supported Cloud Platforms

Operator Interface

Construction

Technical Information